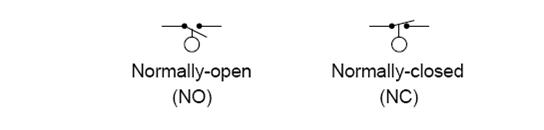

Decoding the Normally Closed Liquid Level Switch Symbol

Ever find yourself staring blankly at a schematic, utterly baffled by a cryptic symbol that looks suspiciously like a sideways toilet float? Chances are, you've encountered the normally closed liquid level switch symbol. This unassuming diagram represents a crucial component in countless systems, from industrial processes to the humble coffee maker. But what secrets does this symbol hold? Let's dive in.

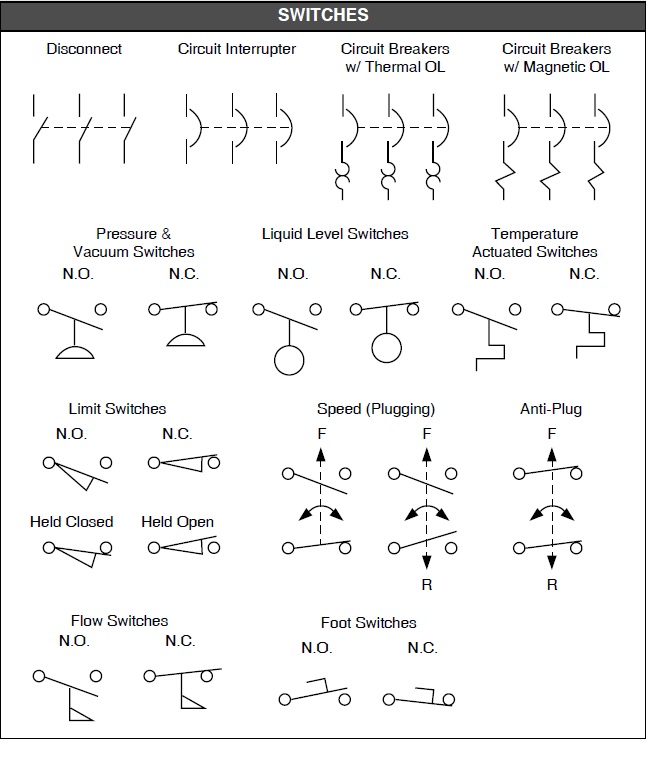

The normally closed (NC) liquid level switch symbol is more than just lines on paper; it’s a shorthand for a mechanism that detects the presence or absence of liquid. Imagine a tiny sentinel, constantly monitoring the fluid level and springing to action when the liquid drops below a certain point. This simple function is the backbone of countless automated systems, ensuring everything from proper tank filling to preventing catastrophic overflows.

These switches operate on a simple yet elegant principle. In their resting state, with sufficient liquid present, the switch's internal contacts are closed, completing an electrical circuit. When the liquid level drops below the designated point, the float mechanism activates, opening the contacts and breaking the circuit. This change in electrical state signals other components in the system to take action, such as turning on a pump or triggering an alarm.

Understanding the normally closed liquid level switch symbol is crucial for anyone working with fluid control systems. Whether you're a seasoned engineer or a curious DIY enthusiast, knowing how to interpret this symbol is key to troubleshooting existing systems and designing new ones. This seemingly simple symbol embodies a critical function, ensuring efficient and safe operation across various applications.

Historically, liquid level control relied on manual observation and intervention. The advent of automated level switches was a game-changer, allowing for more precise control and freeing up human operators from constant monitoring. The normally closed configuration, in particular, became popular for its fail-safe nature. In the event of a power failure or system malfunction, the switch defaults to its closed state, often preventing overflows and other potentially hazardous situations.

A typical normally closed liquid level switch consists of a float, a stem, and a set of electrical contacts. The float's buoyancy causes it to rise and fall with the liquid level. The stem connects the float to the contacts, translating the float's movement into the opening and closing of the electrical circuit. Different types of floats and contact mechanisms cater to various liquids and operating environments.

Three key benefits of employing normally closed liquid level switches are: Overflow Prevention (example: sump pump control), Empty Tank Protection (example: preventing pump damage from running dry), and Automated Filling (example: maintaining a consistent water level in a cooling tower).

Implementing a normally closed liquid level switch typically involves mounting the switch in the desired location, connecting the electrical wiring, and adjusting the switch point to the required liquid level. Testing the switch's operation is essential to ensure proper functionality.

Advantages and Disadvantages

| Advantages | Disadvantages |

|---|---|

| Fail-safe operation | Limited to detecting liquid presence/absence, not precise level measurement |

| Simple and reliable | Potential for float sticking or malfunction |

| Cost-effective | Sensitivity to turbulence or wave action |

Five Best Practices: 1. Select the appropriate switch type based on the liquid and environment. 2. Ensure proper mounting to avoid interference. 3. Use correctly sized wiring for the electrical load. 4. Regularly inspect and maintain the switch. 5. Test the system thoroughly after installation.

Real Examples: 1. Sump pumps 2. Coffee makers 3. Industrial tanks 4. Boilers 5. Aquariums

Challenges and Solutions: 1. Float sticking (Solution: clean or replace the switch). 2. False triggering due to turbulence (Solution: use a baffle or stilling well). 3. Wiring issues (Solution: check connections and wiring gauge). 4. Inaccurate switching point (Solution: recalibrate the switch). 5. Switch failure (Solution: replace the switch).

FAQs: 1. What is a normally closed switch? 2. How does a liquid level switch work? 3. What are the different types of liquid level switches? 4. How do I choose the right liquid level switch? 5. How do I install a liquid level switch? 6. How do I troubleshoot a liquid level switch? 7. What are the common problems with liquid level switches? 8. Where can I buy liquid level switches?

Tips and Tricks: Consider factors like temperature, pressure, and chemical compatibility when selecting a switch. Regularly inspect the switch for signs of wear and tear. Ensure proper wiring and grounding to prevent electrical hazards.

The normally closed liquid level switch symbol, though seemingly small, represents a vital component in numerous applications. From managing industrial processes to safeguarding household appliances, these switches play a crucial role in ensuring efficient and safe liquid level control. Understanding their function, operation, and symbolic representation is essential for anyone involved in designing, maintaining, or troubleshooting fluid systems. By following best practices, addressing potential challenges, and staying informed about the latest advancements, you can harness the full potential of these unassuming yet powerful devices. Whether you're an engineer, technician, or simply a homeowner, taking the time to understand this symbol will undoubtedly pay dividends in the long run, ensuring smooth operation and preventing costly or even dangerous situations. So, next time you see that sideways toilet float on a schematic, you'll know it's not just a random squiggle – it's a symbol of reliable and efficient liquid level management.

Humpy dry fly pattern the unsinkable truth

Surfs up your guide to finding the perfect surfboard for sale in the usa

Navigating the complexities when the woman you love is already married