Decoding the NC Pressure Switch Symbol: A Comprehensive Guide

Ever stared at a wiring diagram and felt lost in a sea of cryptic symbols? You're not alone. One particularly important symbol, often overlooked yet critical in many systems, is the normally closed (NC) pressure switch symbol. Understanding this small glyph can unlock a world of insight into how pressure control systems operate. This guide aims to demystify the NC pressure switch symbol and its function.

The NC pressure switch symbol indicates a switch that, in its default state, without any external pressure applied, completes an electrical circuit. Imagine it like a door held shut by a spring. When pressure reaches a predetermined setpoint, the "door" opens, breaking the circuit. This seemingly simple mechanism is the backbone of countless applications, from HVAC systems to industrial machinery.

But what does "normally closed" actually mean in practice? Think of it this way: when the pressure is below the trigger point, the switch acts as a closed bridge, allowing current to flow. This "normally closed" state is crucial because it allows systems to operate in a default mode until pressure changes dictate otherwise.

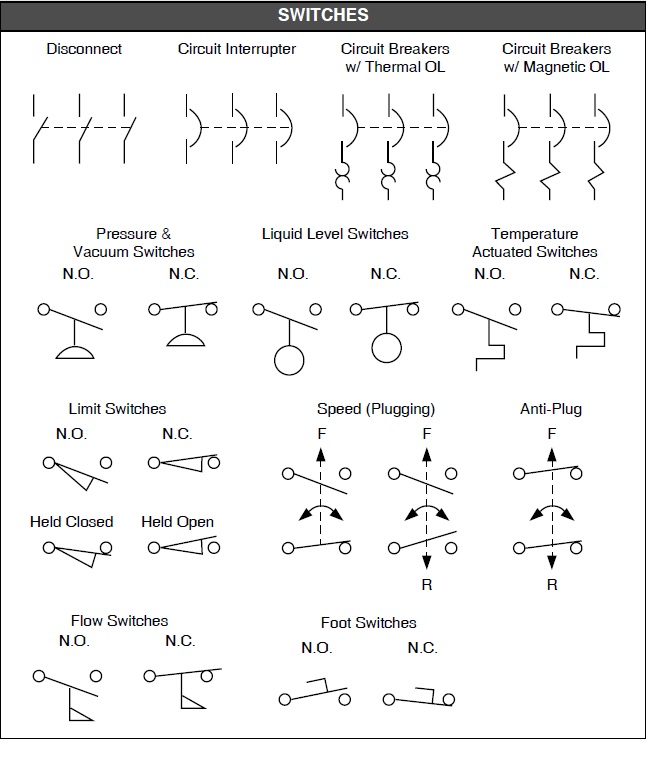

The NC pressure switch symbol is typically represented as a small circle with two perpendicular lines extending from it. One line features a small break, indicating the switch's ability to open the circuit. Variations of the symbol might exist depending on the specific application and diagramming standard, but the core concept of a normally closed contact remains consistent.

Understanding this symbol isn’t just about deciphering diagrams; it’s about grasping the underlying logic of pressure control. From ensuring safety mechanisms are engaged to automating complex industrial processes, the NC pressure switch plays a pivotal role.

The history of pressure switches is intertwined with the development of industrial automation. Early pressure control systems relied on mechanical levers and valves. As electrical systems became more prevalent, the need arose for a switch that could translate pressure changes into electrical signals. This led to the development of pressure-activated electrical switches, including the NC type. These switches offered improved accuracy, reliability, and the ability to integrate seamlessly with evolving electrical control systems.

The NC pressure switch configuration is crucial in applications where safety is paramount. For example, in a boiler system, an NC pressure switch connected to a fuel supply line ensures that the fuel flow is cut off if the pressure drops below a safe level, preventing potential hazards. The "normally closed" state guarantees the system remains safe even in the event of a power outage or switch malfunction.

A simple example of an NC pressure switch in action is in an air compressor. When the air pressure in the tank reaches the desired level, the NC pressure switch opens, cutting power to the compressor motor. This prevents overfilling and potential damage. When the pressure drops below the setpoint, the switch closes again, restarting the compressor.

One benefit is enhanced safety as explained above. Another is automated control – the NC pressure switch allows for automated system responses to pressure changes, eliminating the need for manual intervention. Finally, it offers increased efficiency by automatically controlling processes based on pressure levels, optimizing resource usage.

Advantages and Disadvantages of NC Pressure Switch Configuration

| Advantages | Disadvantages |

|---|---|

| Enhanced Safety | Potential for False Triggering (due to debris or fluctuations) |

| Automated Control | Requires Periodic Inspection and Maintenance |

| Increased Efficiency | Limited to On/Off Control (no variable pressure regulation) |

Five Best Practices for Implementing NC Pressure Switches:

1. Correct Pressure Range Selection: Ensure the switch's operating pressure range aligns with the system requirements.

2. Proper Mounting: Mount the switch securely to minimize vibrations and ensure accurate readings.

3. Wiring Accuracy: Double-check all wiring connections to avoid malfunctions and ensure proper circuit operation.

4. Regular Inspection: Periodically inspect the switch for signs of wear, damage, or debris buildup.

5. Calibration: Calibrate the switch according to manufacturer recommendations to maintain accuracy.

Frequently Asked Questions about NC Pressure Switches:

1. What does NC stand for in a pressure switch? NC stands for Normally Closed.

2. How does an NC pressure switch work? It opens the circuit when pressure reaches a set point.

3. What are common applications of NC pressure switches? HVAC systems, air compressors, and safety systems.

4. How do I test an NC pressure switch? Use a multimeter to check continuity across the switch terminals.

5. How do I choose the right NC pressure switch? Consider pressure range, electrical ratings, and media compatibility.

6. What is the difference between an NC and NO pressure switch? NC closes the circuit below the setpoint, NO opens it.

7. What is the symbol for an NC pressure switch? A circle with two perpendicular lines, one with a break.

8. What are some troubleshooting tips for NC pressure switches? Check wiring, inspect for debris, and verify pressure readings.

Tips and Tricks: Regularly check the pressure switch's specifications and datasheets for detailed information. Consult with experienced technicians for complex installations or troubleshooting.

In conclusion, the seemingly simple NC pressure switch symbol represents a vital component in various control systems. Understanding its function, recognizing its symbol in diagrams, and implementing best practices for its use are crucial for ensuring safe, efficient, and reliable operation. From protecting against potential hazards in industrial settings to automating everyday tasks in residential appliances, the NC pressure switch silently plays a critical role. By understanding this small but mighty symbol, we gain a deeper appreciation for the intricate world of pressure control and the technologies that shape our modern lives. Its importance cannot be overstated, impacting both safety and efficiency in numerous applications. Take the time to familiarize yourself with this crucial component and its role in the machinery around you – you might be surprised by how much you learn about the world of automated systems. By understanding the nuances of NC pressure switches, you'll be better equipped to troubleshoot issues, maintain systems, and optimize their performance.

Mastering the art of friendly roasting

Unveiling your hidden self shadow work therapy explained

Nc retiree payment schedules a comprehensive guide