Decoding the Mercury 75 HP Outboard Water Pump Impeller

Ever wondered about the unsung hero that keeps your Mercury 75 HP outboard engine purring? It's not the horsepower, the sleek design, or even the fuel injection. It's a small, often overlooked component: the water pump impeller. This rubber marvel is the heart of your engine's cooling system, tirelessly circulating water to prevent overheating and ensuring smooth operation.

The Mercury 75 HP outboard, known for its reliability and power, relies heavily on this crucial component. Without a properly functioning impeller, your boating adventures could be cut short by engine damage. This article delves into the intricacies of the Mercury 75 HP outboard water pump impeller, exploring its function, maintenance, and troubleshooting.

Imagine this: you're out on the open water, the sun is shining, and the fish are biting. Suddenly, your engine starts to sputter, and the tell-tale stream weakens. This could be a sign of a failing water pump impeller. Understanding the importance of this small but mighty component can save you from a costly repair and a ruined day on the water.

The impeller for a Mercury 75 HP outboard is specifically designed to handle the demands of this powerful engine. Its intricate design, typically made of a durable rubber compound, allows it to efficiently draw water from the lake or ocean and circulate it through the engine block, dissipating heat and maintaining optimal operating temperature. The impeller's vanes, or blades, are precisely engineered to generate the necessary flow for effective cooling.

Over time, impeller blades can wear down due to constant contact with water, debris, and corrosion. Regular inspection and replacement are crucial to prevent impeller failure. A worn or damaged impeller can lead to overheating, which can cause serious engine damage, including warped cylinder heads, scored pistons, and even catastrophic engine failure.

The history of the outboard motor water pump impeller parallels the development of outboard engines themselves. As engines became more powerful, the need for efficient cooling systems grew. The impeller emerged as a compact and effective solution, enabling higher horsepower and improved performance. Early impellers were simpler in design, but advancements in materials and engineering have led to the robust and reliable impellers we have today.

Replacing a Mercury 75 HP outboard water pump impeller is a relatively straightforward task that can be performed by a DIY enthusiast with basic mechanical skills. Several online resources and videos provide step-by-step instructions. However, if you are not comfortable working on your outboard, it's always best to consult a qualified marine mechanic.

One key benefit of regularly inspecting and replacing your impeller is preventing catastrophic engine failure due to overheating. Another benefit is maintaining optimal engine performance. A properly functioning cooling system ensures the engine runs at its peak efficiency, providing reliable power and fuel economy. Lastly, regular impeller maintenance extends the overall lifespan of your outboard engine, saving you money in the long run.

Advantages and Disadvantages of Regular Impeller Maintenance

| Advantages | Disadvantages |

|---|---|

| Prevents costly engine repairs | Requires some time and effort |

| Extends engine lifespan | Small cost for replacement parts |

| Maintains optimal engine performance |

Best Practices:

1. Inspect your impeller annually or every 100 hours of operation.

2. Replace your impeller every two years, regardless of usage.

3. Use a quality impeller designed specifically for your Mercury 75 HP outboard.

4. Always use a new impeller gasket during installation.

5. Apply marine grease to the impeller shaft to ensure smooth operation and prevent premature wear.

FAQ:

1. How often should I replace my Mercury 75 HP outboard water pump impeller? Every two years or 100 hours, whichever comes first.

2. What are the signs of a failing impeller? Weak or no tell-tale stream, overheating engine, and decreased performance.

3. Can I replace the impeller myself? Yes, with basic mechanical skills and the right tools.

4. What type of impeller should I use? A Mercury-approved impeller designed for your specific engine model.

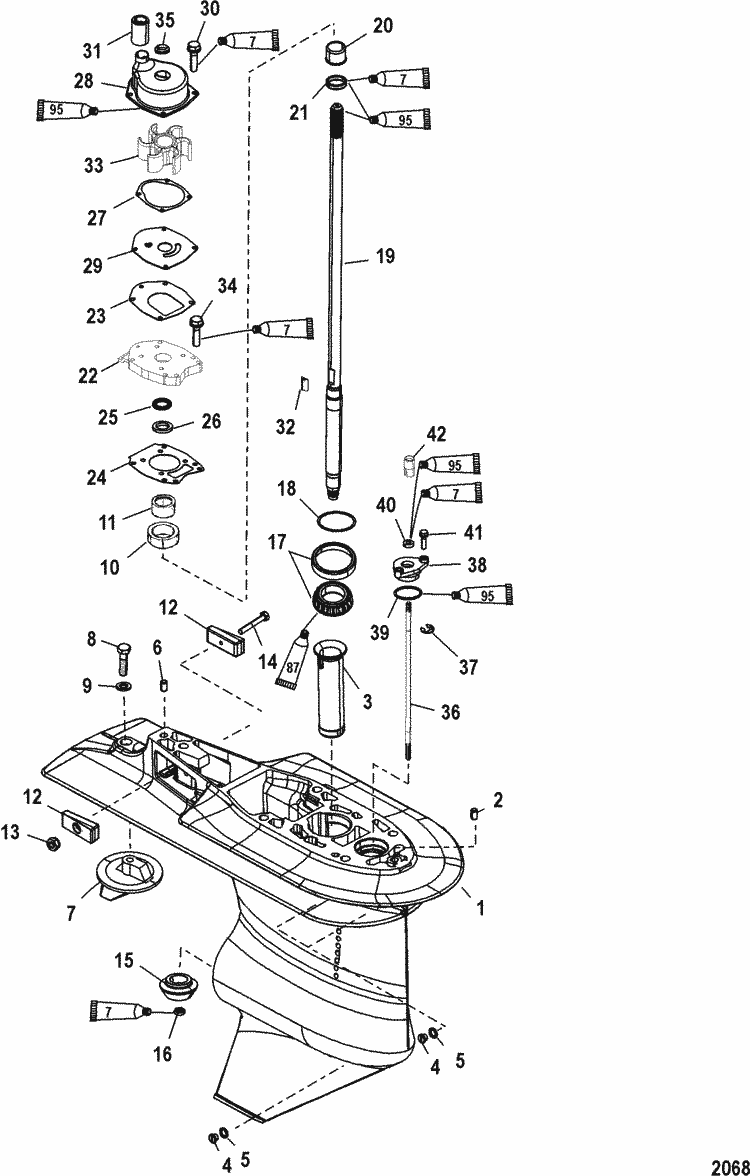

5. How do I inspect my impeller? Remove the lower unit and inspect the impeller for wear, cracks, or damage.

6. What causes impeller failure? Normal wear and tear, debris, corrosion, and lack of lubrication.

7. Where can I buy a replacement impeller? From authorized Mercury dealers, marine supply stores, or online retailers.

8. What happens if I run my engine with a bad impeller? Overheating, which can cause serious engine damage.

Tips & Tricks: When installing a new impeller, lubricate it with glycerin or soapy water to protect the vanes and ensure proper seating. Inspect the impeller housing for debris or corrosion. Carry a spare impeller on board for emergencies.

In conclusion, the Mercury 75 HP outboard water pump impeller, while a relatively small and inexpensive part, plays a critical role in maintaining the health and performance of your engine. Regular inspection and replacement are essential preventative measures that can save you from costly repairs and ensure countless hours of enjoyable boating. Understanding the function and importance of this crucial component empowers you to take proactive steps in maintaining your outboard engine, ensuring reliable performance and extending its lifespan. Don't underestimate the power of this small but mighty component. Invest in regular maintenance and protect your investment in your Mercury outboard. Your boating adventures will thank you.

New couple in 5b book review a fresh perspective

Conquer your colorado driving test ace the exam

Rock that silver fox mastering the ash grey hair look for men

.jpg)